Brand:D&H Adhesive Controlling Machinery

Model:QCB-3500

Applications:T8 tube 、T10 tube

Suitable Material:One-component silicon

Update:2015-07-11

Browse

1. High precision controller ensures glue dispensing accurately;

2. Accurate position and high speed six-heads movement with simple operation

3. Universal use

4. Easy program & operation;

5. Other functions can be customized to meet up customers' special requirements.

Working Area: 1500*1500*30,Customization is available based on clients requirement.

Running Path:The machine can make dot and line etc.

Moving Speed:0-300mm/s

Repeatability:±0.001ML

Air Pressure:0.5-0.7Mpa

Weight:250KG Roughly

Ratio:Pneumatic Supply

Repeatability:±1%

Power Input:AC220V 50-60Hz

Dimension:500*400*400mm

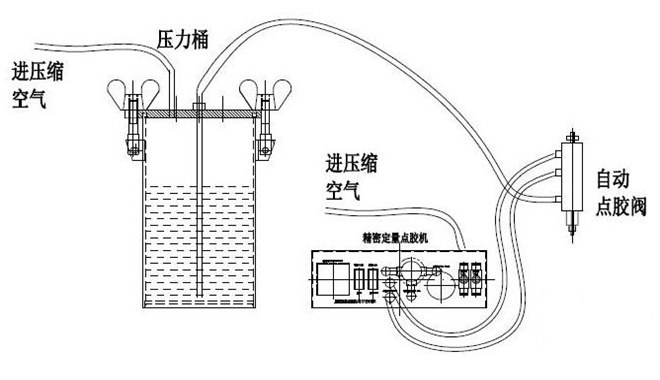

1.Put the glue with the package inside the tank, cover it well, set the valve into the fixture.

2.Edit the program according to the demanded running path and save the program when it finished.

3.Adjust the controller according to demanded glue amount in the unit product, and save the data when setting is finished.

4.Make trial production to check if everything goes well.

1.Robotic Arm

2.Valve

3.Needle

4.Glue-pressing Tank

5.Controller

1.Multi-head nozzle

2.Heating

1.Warranty: 1 year

2.Maintenance for life

3.Monthly Training

4.Quick response to your problems【Contact】