Brand:D&H Adhesive Controlling Machinery

Model:PJL-300GJG

Applications:Capacitor, power supply, transformers, ignition coil, ignition coil, ballast, the inductance coil, circuit board

Suitable Material:Two-component adhesive,silicone, epoxy, PU, etc

Update:2016-03-04

Browse

1. It is a fully automatic liquid controlling system with metering and mixing in vacuum condition .

2. Mix glue A & B evenly;

3. Precise movement with high speed and easy adjustment;

4. Can be universally used for Ignition coil,capacitor and transformer.

5. Easy program and operation;

6. Memory function, non-regular mode, glue mode , liquid-level warning;

7.More functions can be available to meet up with customer's requirement.

Working Area: 500*500*30mm,Customization is available based on clients requirement.

Mixing Method:Static /Dynamic optional

Running Path:Machine can make dot, circle, pulse signal etc.

Moving Speed:0-300mm/s

Repeatability:±1%

Mixing Accuracy:±1%

Tank Capacity:TankA25L、TankB10L,Customization is available based on clients requirement..

Ratio:1:1 - 1:10

Gluing Speed:5-66g/5s adjustable

Air Pressure:0.5-0.7Mpa

Power Input:AC220V 50-60Hz

Dimension:1500*1200*1500mm

Weight:250KG Roughly

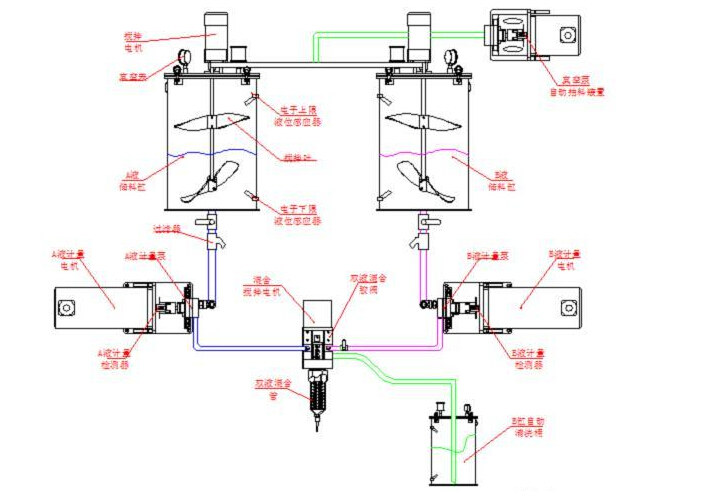

1.Put glue A and B into the tank A and B separately; the function devices on the tanks will ensure the liquid be kept well.

2.Glue A and B will be drawn out by two sets of metering pump according to demanded weight ratio;

3.Glue A & B mixes with each other evenly in the mixer pipe; the mixture is dispensed into the programming running path via the robotic arm.

4.The machine can automatically achieve the demanded potting process by setting the glue amount and program.

1.High Precision Plunger Pump

2.Three-axis robotic arm

1.Vacuum

2.Heating

3.Self-cleaning

4.Mixing

1.Warranty: 1 year

2.Maintenance for life

3.Monthly Training

4.Quick response to your problems【Contact】