Brand:D&H Adhesive Controlling Machinery

Model:PGB-700

Applications:Capacitor、Driver、Transformer、Ignition coil、Stabilizer,Circuit

Suitable Material:AB Two-components Glue、Silicone、Epoxy、PU etc

Update:2015-07-10

Browse

1、Accuracy ratio,mixing&potting integration,achieve real full automation

2、Stir evenly,avoid workers matching not accurate,resulting in some waste.

3、High Precision,High Speed,Operating Easily

4、Universally used,suitable for conventional capacitor,reversing radar,circuit board etc

5、The programming and operation are simple,anyone can operate

6、Auto-counter function,Non-standard mode,;Liquid level alarm

7、Optional Function:Vacuum,Heating,Programmable Running Path

Working Area: 700*700*30mm,Customization is available based on clients requirement.

Mixing Method:Static、Dynamic

Running Path:Machine can make dot, circle, pulse signal etc.

Moving Speed:0-300mm/s

Repeatability:±1%

Mixing Accuracy:±1%

Tank Capacity:Tank A25L、TankB 10L,Customization is available based on clients requirement.

Ratio:1:1 - 1:10

Gluing Speed:5-66g/5s adjustable

Air Pressure:0.5-0.7Mpa

Power Input:AC220V 50-60Hz

Dimension:1500*1200*1500mm

Weight:250KG Roughly

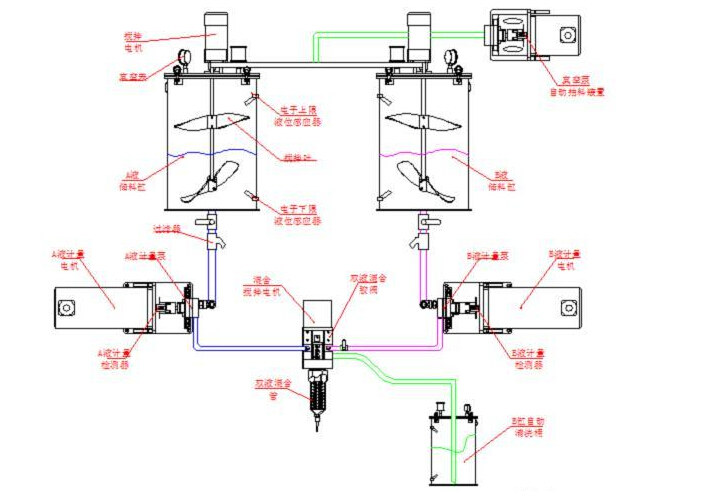

1.Put glue A and B into the tank A and B separately; the function devices on the tanks will ensure the liquid be kept well.

2.Glue A and B will be drawn out by two sets of metering pump according to demanded weight ratio;

3.Glue A & B mixes with each other evenly in the mixer pipe; the mixture is dispensed into the programming running path via the robotic arm.

4.The machine can automatically achieve the demanded potting process by setting the glue amount and program.

1.High Precision Plunger Pump

2.Three-axis robotic arm

1.Vacuum

2.Heating

3.Self-cleaning

4.Mixing

1.Warranty: 1 year

2.Maintenance for life

3.Monthly Training

4.Quick response to your problems【Contact】