Glue potting machine what we call A&B glue potting machine , double liquid potting machine or two-component glue potting machine . It is a fully automatic liquid controlling machine which can be sealed,fixed products with waterproof by dispensing , coating ,potting glue to the surface or internal of products . We normally use two-component glue . Glue potting machine can be worked on irregular graphics including dot , line ,arc , circle and so on . It is mainly use for adhesive , filling, coating and sealing .

Glue potting machine always use two-component liquid what we call AB glue . Glue A is main glue and glue B is curing liquid . Of course it is same with one-component . The most widely used glue in the market are epoxy, polyurethane, silicon and other glue with ratio on 1:1、2:1、5:1、4:3、10:1 .

1.Put A&B glue into A&B tanks , Tank A and B are with the function to assure glue in good condition .

2.It is use two metering pumps to precise gluing and make sure glue A&B dispense the corresponding weight evenly .

3. Mixing glue A&B evenly through mixed device and automatically positioning by editing the glue trajectory through corresponding mechanical hand.

4. It is setting the corresponding quantitative glue and program to realize automatically positioning to satisfy the glue process .

1.What’s type of glue do you use ? What’s the base characteristic ?

A)One-component or two-component (A&B glue);

B)What is the AB ratio if two-component.

C) What’s the viscosity and density .

D)How long does it start to curing , and what is the completely curing time .

E)What’s the packing of the glue .

2.What’s the glue process technological requirement ?

A)What is the glue accuracy with each product ?

B)What’s the purpose of gluing ? Filling , sealing ,paste,insulation, moisture proof ?

C)How to glue the product .

1、Application for optional

LED piranha module LED display module LED bulb SMD module DIP module LED Street light LED flexible strip LED rigid light LED wall washer 标牌铭牌 Led floodlight LED Segment Display Ballast 汽车灯 太阳能边框 Led underground light Inductance coil 热水器控制器 布料滴胶 T-8 tube light LED guardrail tube Power Supply PCB 硅胶文胸 LED Roller screen SMD paster 汽车齿轮 皮带 挡风玻璃 Q卡 Transformer 洗衣机 LED Advertising light 工艺品 Energy saving lamp Ignition coil 接线盒 LED Tree light 相册 High pressure pack 硅晶片 汽车后桥 鞋子 Capacitance 电磁炉 炉具控制器 冰箱 Mutual inductor 制冷设备

2、Glue type for optional

Double Liquid glue dispenser Three-Axis Glue DispenserPolyurethane glue dispenser Transparent glue dispenser Foam adhesive glue dispenser High viscosity glue dispenser Silicon glue dispenserFully Automatic Glue Dispenser for 5M led high additive glue dispenserEpoxy glue dispenser

3. Glue process for optional

Vacuum Glue Potting Machine Gear Pump Glue Potting Machine Plunger Pump Glue Potting Manual Glue Dispenser Universal Semi-Automatic Glue Dispenser Fully Automatic Glue Potting Machine Fully Automatic Glue Dispensing Line

4.Cost-effective for optional(Cost from high to low :)

Fully Automatic Glue Dispensing Line>Fully Automatic Glue Potting Machine>Universal Semi-Automatic Glue Dispenser>Manual Glue Dispenser

Speed from fast to slow : multi-heads glue dispenser > two heads glue dispenser > single head glue dispenser

Drops always happened when valve closed . The reason may be low concentration of glue , big air-pressure or large diameter of needles.

Narrow needles will effect the flow of the liquid and cause back pressure . It will lead to dropping when the valve closed . Too narrow needles will effect the drainage of air when valve start to work, but it can be solved if change suitable needles .

Conical needles with less back pressure and liquid flow smoothly .

It is better to drainage of the air advance or use no-foam glue or deaeration to avoid the air cause dropping after valve closed .

The problem cause mainly because of the storage flow pressure tank or air pressure is not stable.

Inlet pressure regulating table should be set lower 10-15psi than factory minimum pressure . The pressure in pressure tank should be set upper than the middle pressure of regulating table . It should be avoided to use the pressure lower than the middle pressure of regulating table .

Control pressure of rubber valve at least higher than 60psi to assured glue evenly .

We should check the glue output speed at last . The glue is uneven if the time less than 15/1000s , the output speed more longer , the glue dispensing will be more stable .

It should be changed the pipe from 1/4 to 3/8 if the flow velocity too slowly .

The pipe is the shorter the better if no requirement .

Excessive fluid pressure and short valve opening time may lead to the air infiltration liquid . We can use the conical needles and reduce fluid pressure .

This problem is caused by heavy moisture and recycle instant glue . We should make sure to use new instant glue and wash the pipes with dry acetone . Make sure air dry and add filter between plant air pressure and valve .

Make sure to use black pipeline.

Don’t add new UV glue to old UV glue in pressure tank , we should drain off the old UV glue before pouring new UV glue into pressure tank because the UV glue will produce bubble after a period of time and lead to glue dispensing unevenly .

Normally , it may cause air problem if the needle less than NO.20 . It is better to use large steel needles or conical needles to avoid to use winding needles or teflon needles

It is better to use storage pressure cylinder of methybenzene toluene to self-cleaning one time for each shift . The more frequently cleaning the better .

Dynamic mixing tube

Dynamic mixing tube Static mixing tube

Static mixing tube Manual pressure barrel

Manual pressure barrel Pneumatic pressure barrel

Pneumatic pressure barrel Cylinder plunger pump

Cylinder plunger pump High adhesive glue system

High adhesive glue system Dynamic twin liquids valve

Dynamic twin liquids valve Static twin liquids valve

Static twin liquids valve Needle

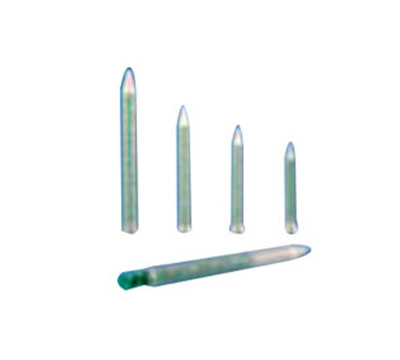

Needle